What is plasma ?

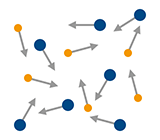

Plasmas, the fourth state-of-matter, are collections of freely moving charged particles(mainly electrons and ions) in which collective phenomena, such as wave, dominate the behavior of the system. Atoms have lost electrons, energy is needed to strip electrons from atoms to make plasma. The energy can be of various origins: thermal, electrical, or light (ultraviolet light or intense visible light from a laser). Plasma are essential to many high-technology applications, one example is fusion energy for which the fuel is high-temperature plasma. Low-temperature plasma are used for a growing number of materials fabrication processes including the etching of complex patterns for micro-electronic and micro-optical components and the deposition of tribological, magnetic, microwave generation, destruction of toxic wastes, chemical synthesis, lasers, ion thrusters, and advanced design accelerators for fundamental particle research.

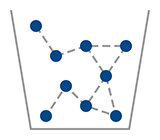

Solid

Ice H2O

Cold T < 0 deg C.

Molecules Fixed in Lattice

Liquid

Water H2O

Warm 0 < T < 100 deg C.

Molecules Free to Move

Gas

Steam H2O

Hot > 100 deg C.

Molecules Free to Move,

Large Spacing

Plasma

Ionized Gas

H2-H++H+++2e-

Hotter > 100,000 deg C.

e > 10 electron volts

Ions and electrons Move

Plasma in nature

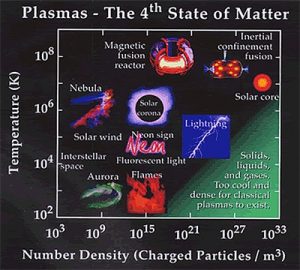

Plasma is by far the most common form of matter. Plasma in the stars and in the tenuous space between them makes up over 99% of the visible universe and perhaps most of that which is not visible. On earth we live upon an island of “ordinary” matter. The different states of matter generally found on earth are solid, liquid, and gas.

We have learned to work, play, and rest using these familiar states of matter. Sir William Crookes, an English physicist, identified a fourth state of matter, now called plasma, in 1879. Plasma temperature and densities range from relatively cool and tenuous (aurora borealis) to very hot and dense (the central core of a star). Ordinary solids, liquids, and gases are both electrically neutral and too cool or dense to be in a plasma state. The word “PLASMA” first applied to ionized gas by Dr. Irving Langmuir, an American chemist and physicist, in 1929.

Natural plasma examples include lightning, fire, and aurora borealis

Cold plasma examples are: fluorescent light, high-intensity arc lamp and some of street lights.

PLASMA – A New Generation Technology

PLASMA SYSTEM – Gas (Argon, Oxygen, Hydrogen, CF4 and Other Flourine Gas)

A Plasma is a partially ionized gas containing ions, electrons, atoms, neutrals. To enable the gas to be ionized in a controlled and qualitative manner, the process is carried out under vacuum conditions, A vacuum chamber is first pumped down via rotary vacuum pump system like (Leybold V-pump) to an absolute vacuum pressure 100 to 0 pa., the gas is then introduced into the chamber by means of mass flow controll valves, pressure is monitored by the vacuum diapharm gauge (piezo electric material) or (load cells), measured pressure is converted to electrical voltage and send to the PLC.

A high-frequency RF generator is then applied to power up and ionized the gas into a plasma, forming an environment that has been referred to as “The Fourth State of Matter”. In the presence of sufficient energy, a solid can be melted to a liquid, a liquid into a gas, and a gas ionized into a plasma.

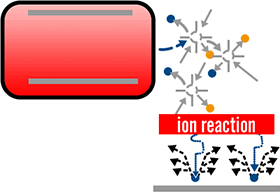

The formed reactive particles react in a direct way with the surface without damaging the bulk properties of the treated base material. The surface modification is limited to the outermost 10 to 1000 angstroms A of the substrate. One distinguishing characteristics of a plasma is a visible glow discharge, with colors ranging from blue-white to dark purple, depending on the type of gas.

Plasma system generally comprise five main components: the vacuum chamber, a vacuum pump, a gas controlling system, RF generator 13.56mhz and PLC controller. Various chamber plates and electrodes are added or adopt to handle particular applications. The chamber is configured to some limited application, configuration may differ to another set mode of treatment applications.

Natural air is Pump Out and vacuum out at the Chamber to approximately absolute vacuum=10 to 0 pa

Reaction Gas is then introduce (Argon), vacuum may go up to more than 100 pa, then stabilized to 10 pa, depend on the amount of gas flow.

Then RF power is

‘ON’ the Gas now

IONIZED and

PLASMA is created

APPLICATION

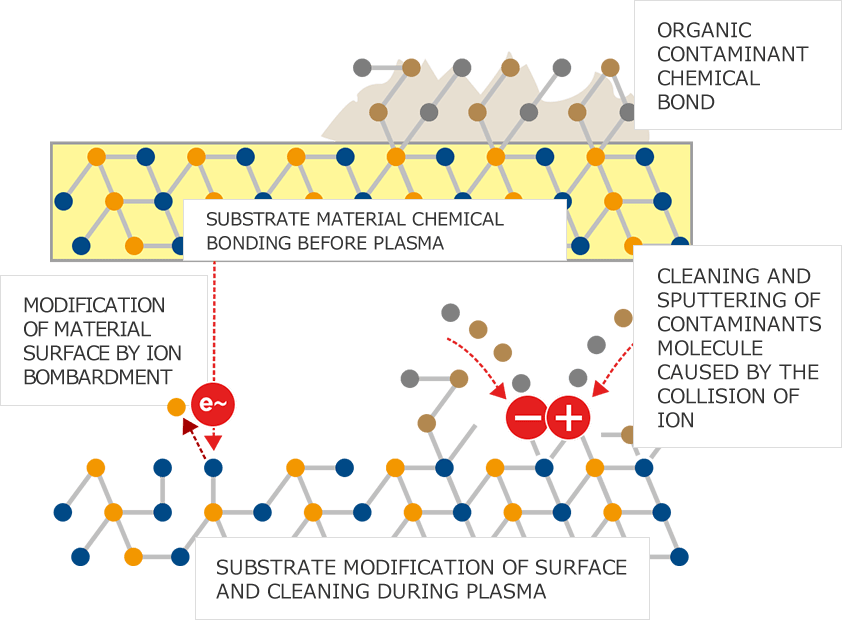

The process of plasma surface modification on materials, substrates, copper, and other plastic products can be divided into some distinct mechanism: e.g.: Cleaning, Etching, Activation

CLEANING

A clean surface on a material is deceptively difficult to attain. Conventional cleaning methods can be incapable of removing certain sursface films, leaving a thin contamination layer. With plasma treatment, it is completely removes contaminants films even from the complex surfaces.

The ability of plasma processing to break down weak covalent bonds in a substrate is also known as ablation. This effects the outer most molecular layer the exposed to the plasma, which boils off and is pump down by the vacuum. Because the chemistry of any layers of surface contamination is also generally made up of weak C-H bonds (finger prints, injection molding additives, oil films can be remove by plasma treatment, thereby leaving behind a uniformly clean and active polymer surface.

WHY PLASMA TREATMENT EVEN WITHOUT CONTAMINANTS

- Plasma grafting (etching and cleaning) – Employs Argon or Helium gas which remove some atomic species from the basic polymer generating reactive and cross-linked surface

- Surface Activition (surface modification) – Employs a reactive gas Oxygen or Nitrogen which creates different functional groups modifying the hydrophilicity and the biochemical reactivity of the surface.

- Plasma Deposition (Coating) – Use gas like Methane can be plasma polymerised, coating the device surface with thin layer of a different polymer

PLASMA ADVANTAGES

- It is environmentally friendly, low energy cost, no waste-disposal

- Operator friendly, with no controllable to chemicals, toxic gas or radiation.

- All process parameters are fully controllable and repeatable

- Cause no substrate damage on the bulk property

- Chambers can be modified to an extensive range of practical geometries small or larger loads.

Economical and ecological aspects of plasma surface treatment

- Low cost for raw materials and low running costs

- Solvent free, dry process

- Extreme low consumption of chemicals (Argon gas tank CIGI size 4 to 6 months at 3% flow)

- Chemicals are inert (not chemically reactive)

MEDICAL

Advance Sterilization Product Equipments, A low low-temperature sterilizer offers faster processing time, enhanced performance and terminal ‘Self Ready’ sterilization, A system for next generation low-temperature hydrogen peroxide gas plasma sterilizer for processing medical devices and surgical instruments. It has a significant faster, 1 hour processing time and enhanced cycle allowing a reduction in inventories of expensive instruments while prolonging the life medical devices. Of course, people will continue to experience the benefits they have come to expect, safety, efficacy and superior materials compatibility.

- Glass pipe tube in a dialysis filters are plasma treated to improve flow of blood to avoid clotting.

- Catheters are treated to enhance liquid flowability

- Preparation for adhesive bonding needles to syringe hubs

- Biocompatibility, The activation of surface to prepare them for cell growth or protein bonding is another important application of plasma modification. Examples of in vitro uses of plasma treatment include preparation of petri dishes and micotiter plates for laboratory experiments or drug-production purposes.

- EX. Nature (Lightning) – Ionization of the air atmosphere especially near the ground where it activates some species of mushroom bacteria spores growth.

PLASTIC INDUSTRY

Surface modification using gas plasma is a versatile process, with system on the market for treating from small components like hubs or balloons up to very large and complex substrates, from fibers, nonwovens, wovens, and paper to plastic foils, plastic polypropylene to some metal holders and handles.

METAL WORKS

The application of Vacuum Arc, Also known as a cathodic arc, the vacuum arc is a device for creating a plasma from solid metal. An arc is struck on the metal, and arc’s high power density vaporizes and ionizes the metal, creating a plasma which sustain the arc. The vacuum arc is different from high-pressure arc because the metal vapor itself is ionized, rather than an ambient gas/ The vacuum arc is used in industry for creating metal and metal compound coatings.

Often metal surfaces becomes contaminated with greases, oil, waxes and other organic compounds as well as oxide layers. For some procedures such as sputtering, varnishing, gluing, printing and coating, bonding, soldering and brazing, it can be fundamentally important to use absolute clean and oxide-free surface.

SEMICONDUCTORS WAFER FABRICATION

Plasma etching is currently widely used in the fabrication of silicon-based circuits. The process is used to produce high-resolution patterns in many of the thin layers of the circuits and to selectively remove masking layers, it is based on the following sequence of microscopic reaction steps. A plasma process is used to transfer lithographically defined patterns into a thin layers of a SILICON material.

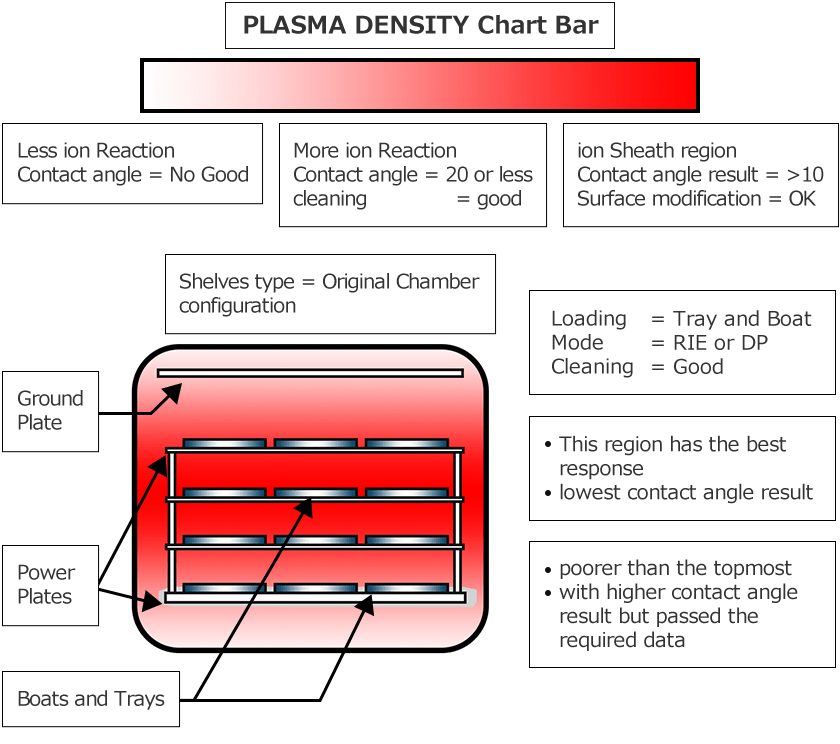

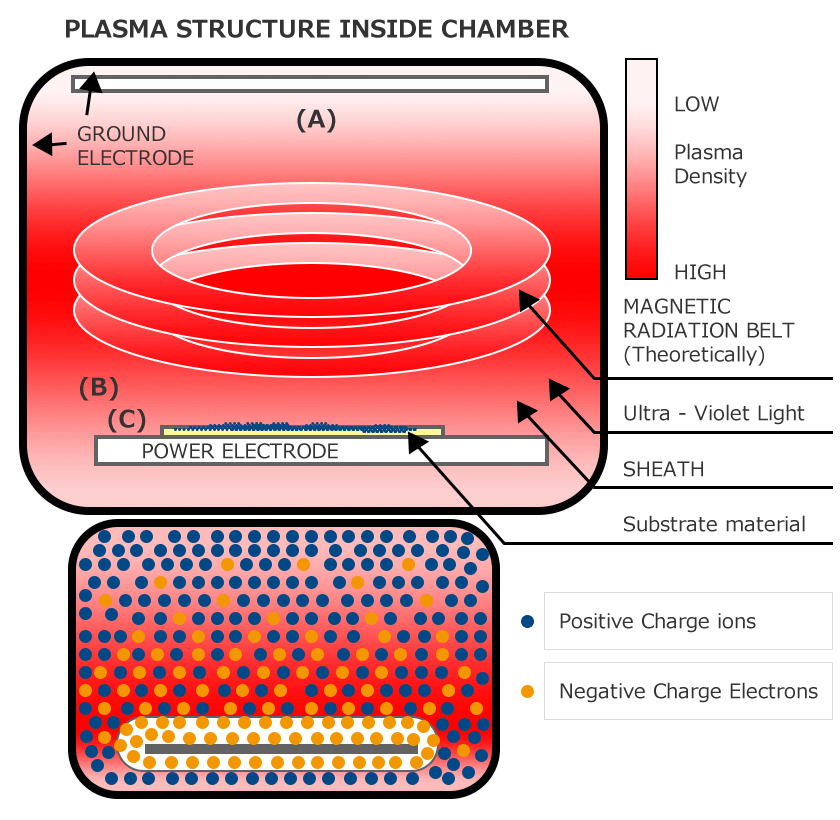

( A ) Upper Region

- Plasma density is lesser as indicate by pale UV light, because there are much more positive charge ions than negative charge electrons, reaction is slow.

( B ) High Plasma

- Region where the most visible UV light emitted by the fast ion reaction. There is approximately equal numbers of negative charge ions and positive charge electrons. Ions gain more acceleration as it approach near the Sheath.

( C ) Lower Region (SHEATH)

- This region is called the SHEATH where there is strong electric field in front or on top of the power electrode,

- Sheaths are of critical importance for plasma etching, since positive ions are accelerated toward the surface when entering a sheath. The accelerated ions bombard the surface with energies that are much greater than thermal energies.

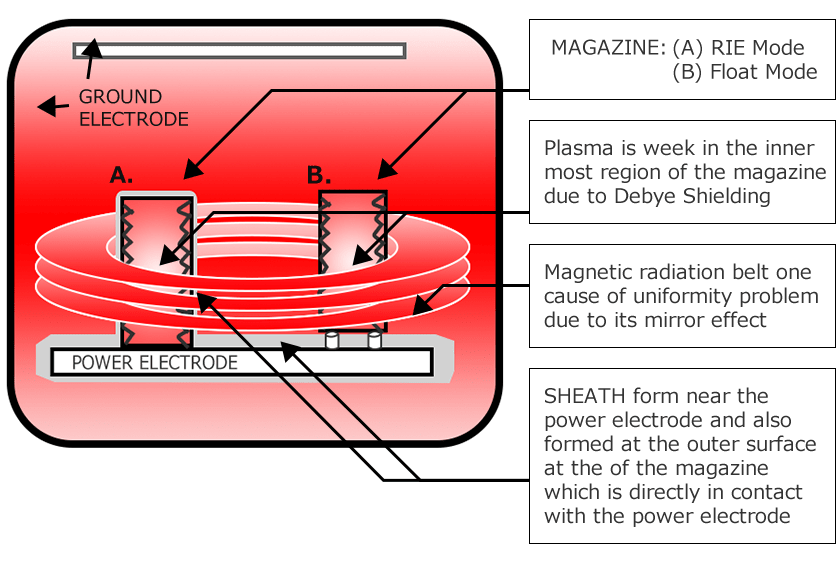

MAGNETIC RADIATION BELT

- Geomagnetic fields lines form by RF electric fields, the plasma is acted upon by electric and magnetic fields created within the plasma itself through localized charge concentration and electric currents that result from the differential motion of the ions and electrons.

- This is one big phenomena that influence the direction of charge particles.

– FACTORS AFFECTING ION REACTION IN THE PLASMA –

RF Power

- Energy source for ionization to excite gas atoms

Why RF

- Ion particles are generally excited with electric fields, but pulsing is needed to compensate charge of ion to counter react before its charge decays.

- Excites ion more violently and radicals

Vacuum

- Vacuum creates an atmosphere to increase boiling point at low temperature

Reaction Gas

- Inert gas if excited in a Plasma invironment creates radical ion

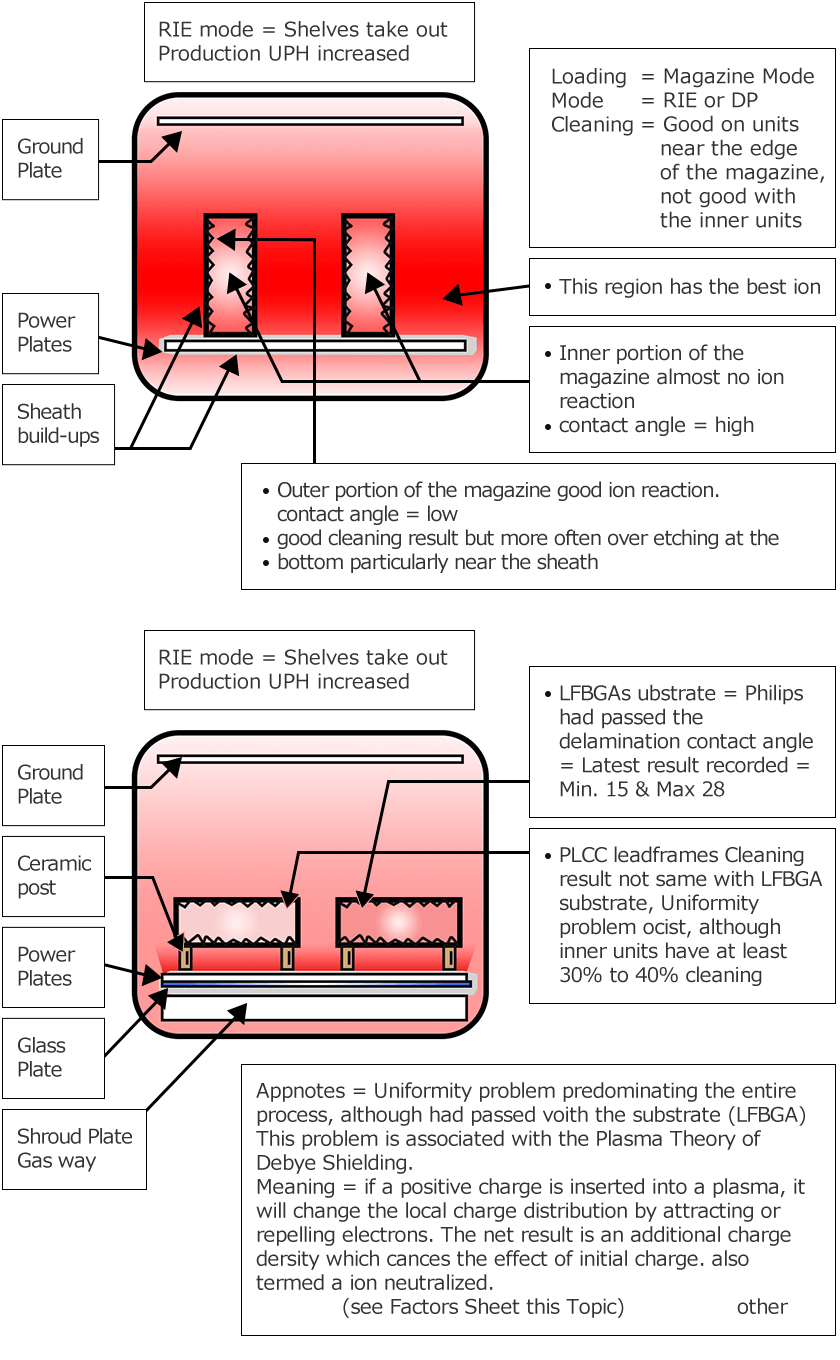

Sheath

- The region of strong electric field in front of material surface in contact with a plasma Its thickness is the Ion Sheath Length.

Debye Shield

- If a plate or metal may it be negative or positive charge is inserted into a plasma, it will change the local charge distribution by attracting or repelling electrons. The net result is an additional negative or positive charge density which cancles the effect of the initial charge at distances large compared to the debye length.

There is a corresponding effect of shielding by ions, which, for various and subtle reasons

Van Allen Belt

- The magnetic belt regions in which charged particles are trapped by the magnetic mirror effect.

Mirror Effect

- A charged particle travelling into an increasing magnetic field will reverse direction and be reflected back, provided its velocity perpendicular to to the field is sufficiently large relative to its parallel velocity. This magnetic mirror effect is a direct result of the adiabatic invariance of the magnetic moment. The mirror effect occurs in some plasmas, since the toroidal magnetic field is stronger on the inboard side than on the outboard side; in this case it gives rise to so-called ” neoclassic” bahavior.