Description

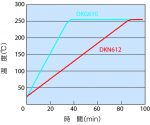

Reduced heating time to 1/2.5, cooling time to 1/4 (compared with conventional company products), horizontal air flow appropriate for loaded operation, the standard oven for production lines supporting multi power supplies. The product lineup includes a silicon free type.

Features of Industrial Forced Convection Oven (Silicorn/Fluoro-rubber Gasket) (DKG610)

- Features

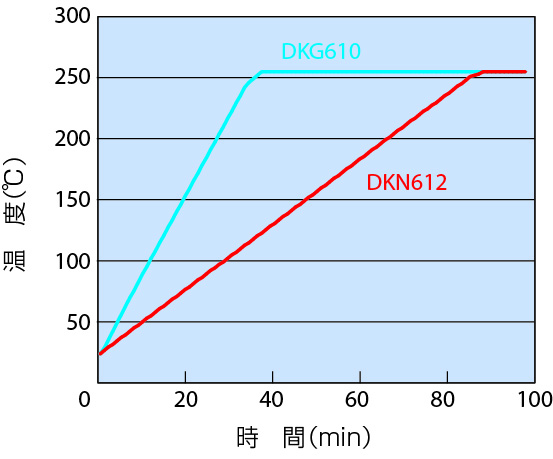

- Standard oven with simple operation whose temperature increase and decrease time has been improved 50% or more compared with conventional products to reduce product takt time.

- Features

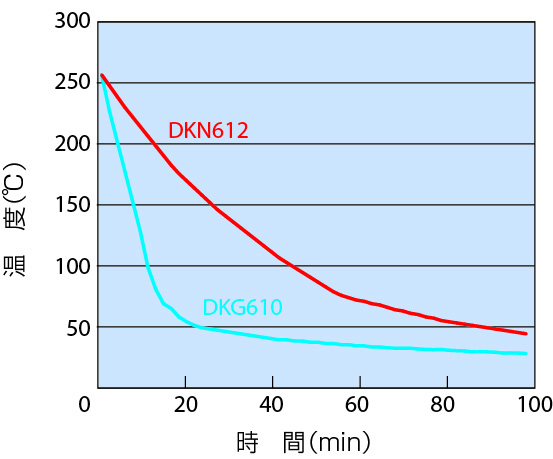

- Temperature increase time has been reduced up to 1/2.5 (at no load, compared with conventional company products), temperature decrease time has also been reduced to 1/4 (at no load, compared with conventional company products). Extensive increase in work efficiency is expected.

- Features

- Employment of a total exhaust system in which air supply and discharge are linked by operation of the manual damper at the front realizes extensive reduction in temperature decrease time.

- Features

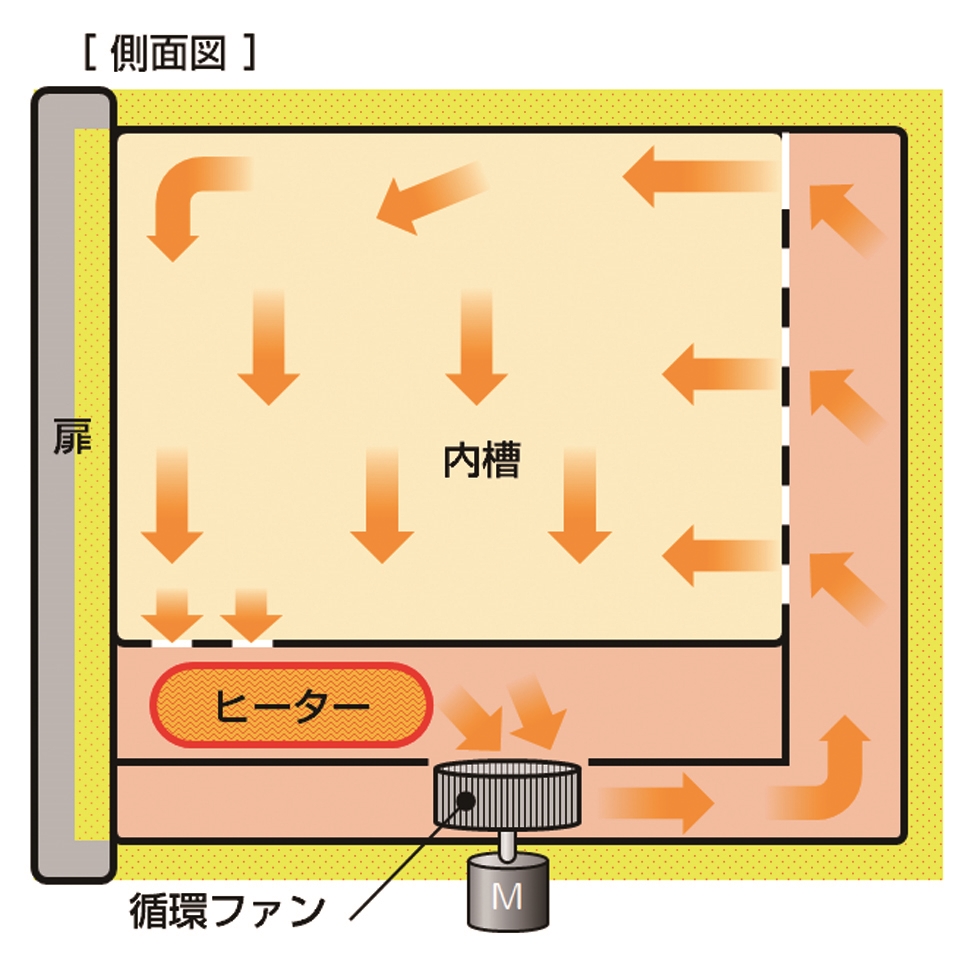

- The horizontal air flow system ideal for processing samples in a magazine rack or a lot of samples realizes high precision temperature performance even at loaded condition.

- Features

- Fluoro rubber is employed for shoulder packing to realize silicon free. (DKG610V/650V/810V/850V)

- Features

- Product lineup includes 610/610V/810/810V for 200 to 220V power supply and 650/650V/850/850V for 230 to 300L 240V to support multiple power supplies.