Description

Standard “Best Seller” ovens – Fully programmable

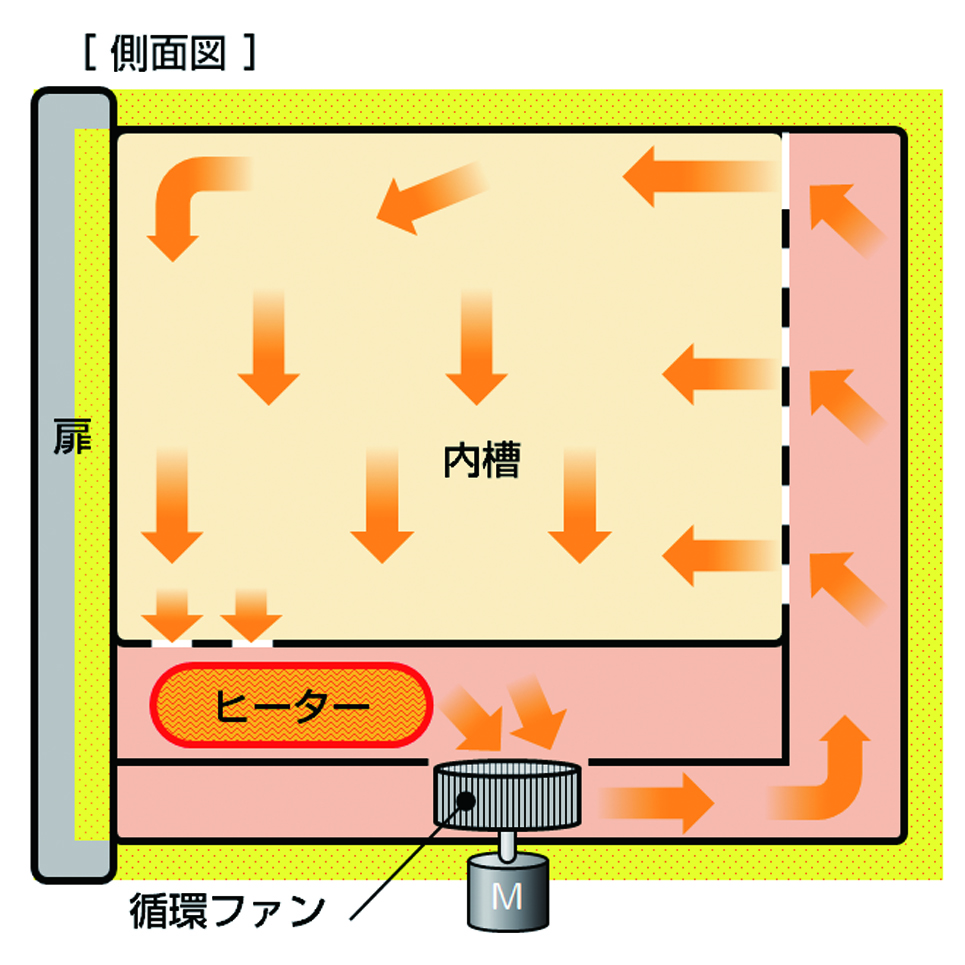

Features of Forced Convection Oven (DKN912)

- Standard forced air convection ovens

- Standard forced air convection ovens are programmable and come with extended functions and safety features.

- Feature

- Best seller based on excellent performance & affordability

- Feature

- Superior temperature accuracy

- Feature

- DKN302/402/602/612 come with observation windows

- Feature

- Programmable PID controller for easy program settings 30-step, 3-pattern program controller with repeat functions

- Feature

- Fixed setting, programmed, Quick Auto stop, Auto stop, and Auto start operating modes with easy control capabilities

- Feature

- Increased safety and Self-diagnostic function

- Feature

- Over-heating prevention and calibration off-set are possible with auxiliary functions

- Feature

- Easy to use and maintain

- Feature

- Built in exhaust ports

- Safety features

- Self diagnosis functions (Temperature sensor abnormal, Heater disconnection, SSR-short) Automatic overheating prevention, Electric leakage breaker with over current protection, Key lock function