Description

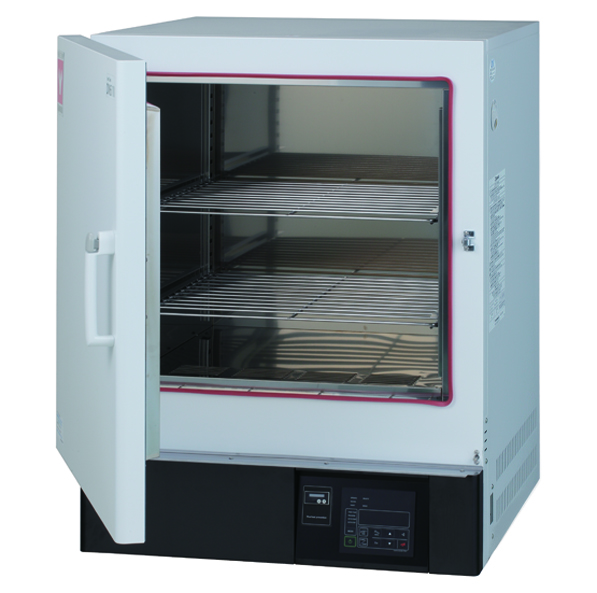

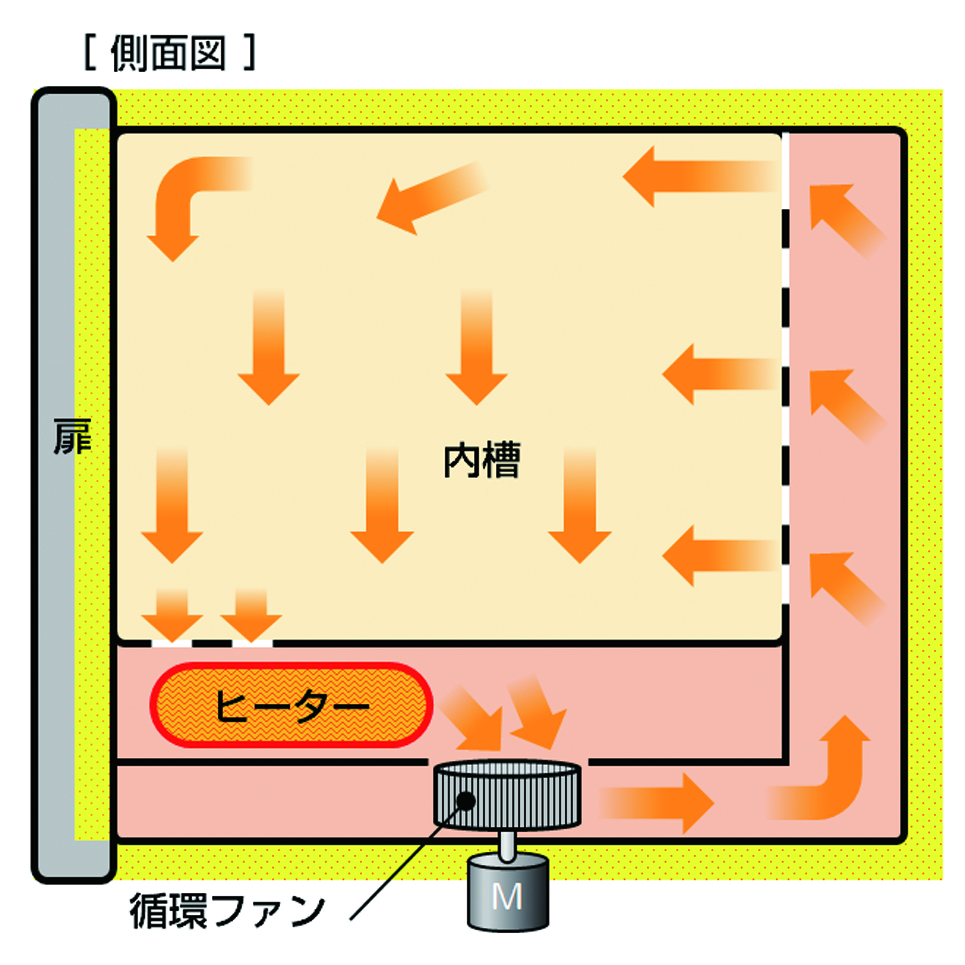

Industrial & Laboratory Forced Convection

Features of Forced Convection Oven (High Temp.) (DN411H)

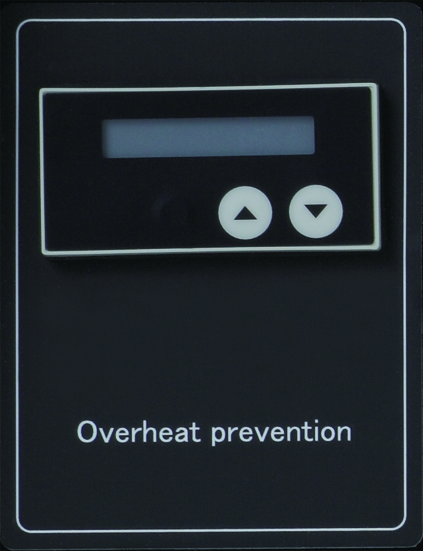

- High precision constant oven

- Due to high precision control system, high performance temperature control is realized, and the CO2 discharge, power discharge can be also displayed at the monitor.

- Feature

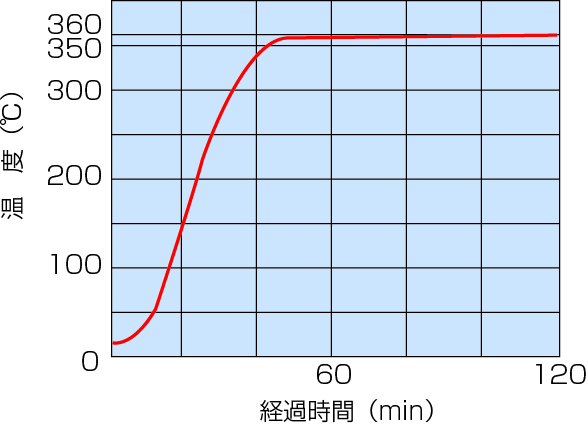

- Suitable for Heat Insulation Test and Curing Process up to 360deg.C.

- Feature

- Simple Operation by Interactive Key Input.

- Feature

- Calibration offset function, power failure recovery mode , the user configuration information and various function are standard added.

- Feature

- Incorporates with maximum 99 steps, 99 patterns program controller with repeat function.

- Feature

- Loaded with Total Operation Hours Timer.

- Feature

- Data acquisition from internal test device is easy because of cable holes.